First off, a shout out to my old friend going back to high school, Errrrnnnn! We used to play cars back then and still love to talk about them now. Too bad he lives many states away in Nevada. He has inspired me to keep my project posts going. Thanks Ern. It’s really nice to be appreciated and to be able to look back on the work accomplished. Plus, I like having online stories for the next caretaker to refer to as time goes by. Onto the Jaguar.

This is how the Jaguar sat in my garage for almost two years. After I first got it running, I drove it for about 10 minutes in the neighborhood before the brakes started locking up. My guess was the fluid heated up in the old rubber lines which caused them to swell just enough to prevent the caliper from relieving pressure. I tried replacing the lines and brake reservoir but the rear calipers were locked up anyway, so out it came, the entire rear sub-frame assembly. Most of the time, I find the older cars easier to work on. They have room to move around and in general were made to service. Not sure if I’d characterize these carry over inboard brakes from the XKE as made-to-service. I mean, come on, brakes are wear items. You have to drop the entire rear assembly to get at the top bolt on the caliper (see pic below). And you can’t change rotors without the calipers off. It was around 1992 that Jaguar finally switched to outboard brakes.

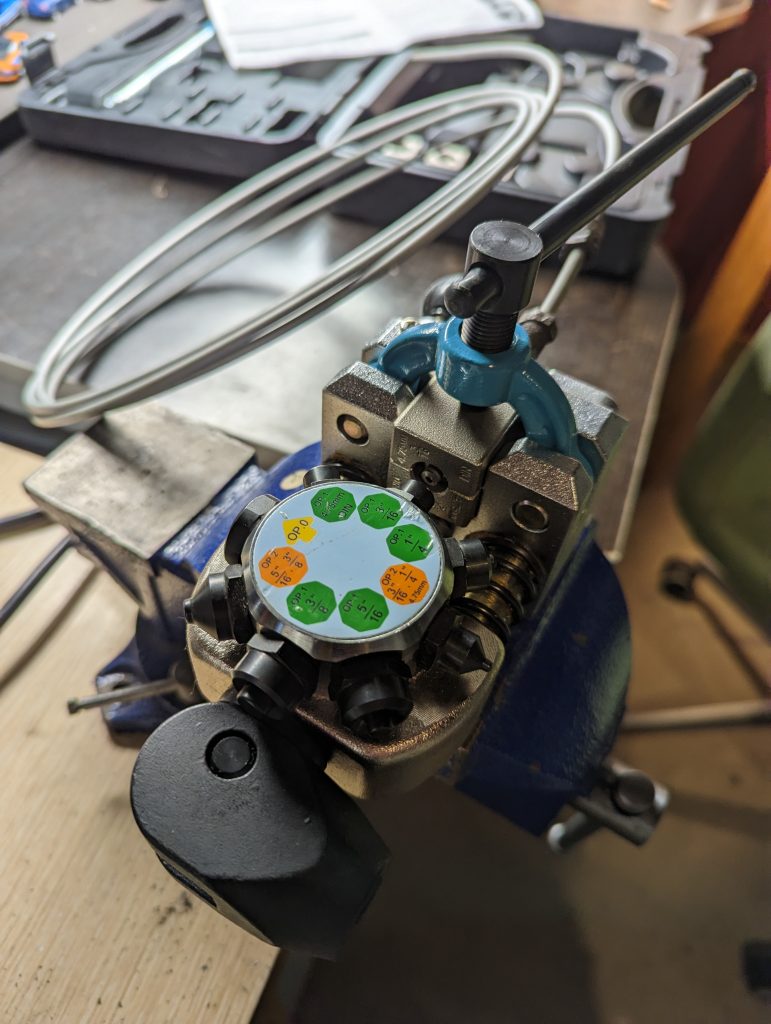

Taking the assembly down wasn’t bad. Eight bolts hold it up. Four bolts disconnect the drive shaft. Uncouple the exhaust pipes and brake lines – out it comes. As they say, reverse it to put it back. In between, pull off the entire suspension so the drive shafts will swing low enough to allow removal of the rotors. Take an open end wrench and hope you have enough leverage to loosen the caliper bolts between the diff and said rotor. Make some new brake lines. Clean, inspect and POR-15 to prevent rust from getting worse. Take a moment while you’re sitting on a 5 gallon bucket, working off the floor in your garage, to reflect on the M1 Concourse opportunity you passed up.

I couldn’t really say why it took me so long to tackle these brakes. It was one of those how do you eat an elephant scenarios for me. If you read the forums they say calipers can be done in anywhere from 4-10 hours. Some say while still on the car, others balk at the notion. Rotors add another layer of complexity. I think I was intimidated by rusty nuts and bolts that were difficult to get wrenches on, let alone my electric impact socket drivers. I vacillated every time I looked at the lump outside my laundry room door. Until one day I picked up a tool, stopped being one and got to work. I made decent progress and enjoyed it. That catapulted me to the next round and the next, until one day it was ready to go back into the car. I seem to recall getting it back up and bolted in was easy but an all day affair. It took several hours to align the exhaust pipes so they hung without resting against the calipers. Time for my first real test drive which I’ll subject you with the next post.

Leave a Reply